YeastPitch

Application

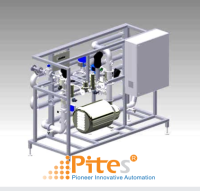

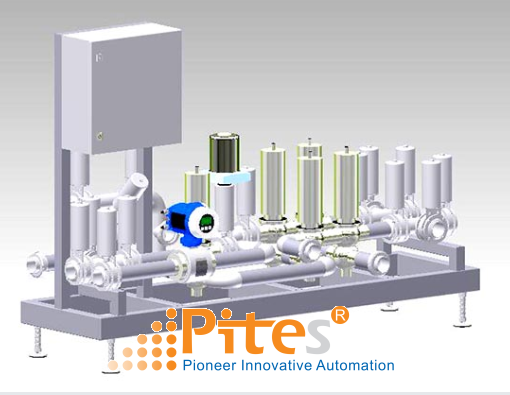

The yeast pitching system YeastPitch doses yeast cells fully automatic and homogeneously into the wort stream.

Description

The yeast pitching unit is a fully automated system that measures and controls the addition of liquid yeast into the wort line with extreme precision. In the standard design the skid is equipped with accurate flow meters. Optionally, turbidity sensors or a live yeast cell monitor can be used. Differential turbidity measurement before and after yeast dosing ensures that the right amount of yeast is dosed into the wort. Variations in the basic turbidity of the wort are automatically compensated for. As an alternative to differential turbidity measurement, the dosed yeast can be controlled by in-line live cell measurement. A specifically designed injector then blends the yeast and the wort together. The yeast cells are homogeneously distributed throughout the wort by a Vortex effect inside the injector. Due to its compact and modular design, the skid can easily be combined with a wort aerating system.

- High precision sensor technology for process control

- Specifically designed Vortex-Venturi injector for yeast cell dosage

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 - 3.000 hl/h |

| Dosing Range Yeast Cells | 10 - 100 Mio./ml |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | in-line O2 measurement; live yeast cell monitor; booster pump; wort aeration |

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652