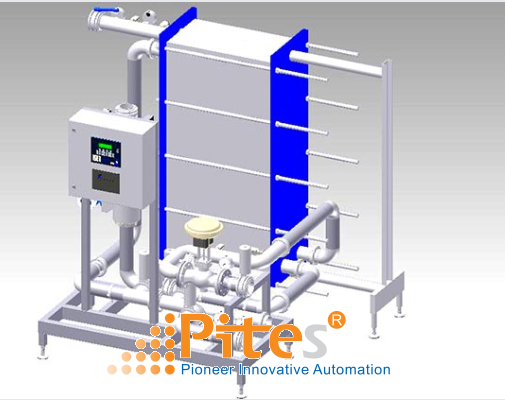

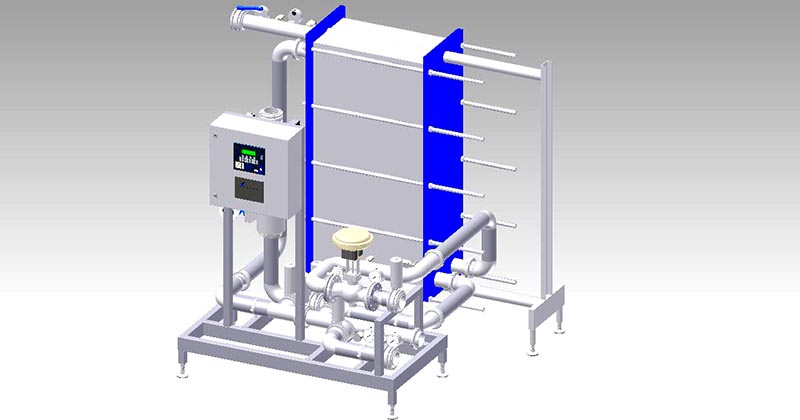

Wort Cooler

Application

The Wort Cooler reduces the temperature of wort to the required pitching temperature. In breweries, cooling is typically performed after wort boiling and trub separation.

Description

For wort cooling a plate heat exchanger is used. The cooling process is done in one or two stages. In a single-stage process cold brewing water is used as the single cooling medium. The brewing water can be cooled to approx. 1 °C in a separate chiller operated with glycol, ammonia or brine. The wort enters the plate heat exchanger at about 100 °C. Due to the interaction of the hot wort and the cold brewing water in the heat exchanger, the temperature of the wort is lowered to approx. 2 - 3 °C while the temperature of the brewing water is raised to about 80 °C. The brewing water is used for the next brew, so the energy is returned to the brewing process. In a two-stage process, the hot wort is first cooled by brewing water to approx. 20 °C and then secondly by glycol, ammonia or brine to the pitching temperature. The warm brewing water can also be used for the next brew.

- High energy efficiency with brewing water as cooling medium

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 - 2.000 hl |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; booster pump; wort cooler; yeast pitching |

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652