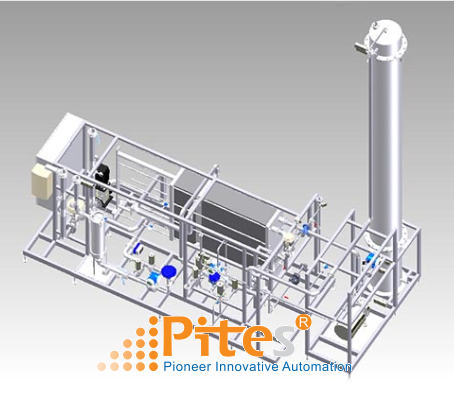

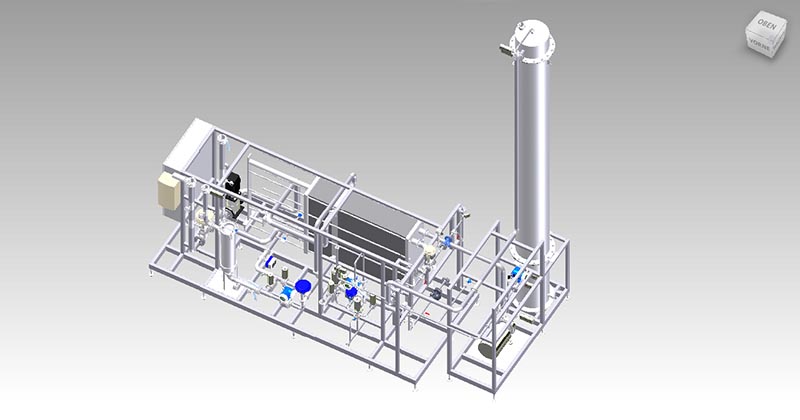

DeGaS-Hot

Application

Dissolved oxygen has adverse impact on flavour stability and shelf life. The deaerations system DeGaS-Hot removes O2 from water that is used for the production of beer and beer-based mixed drinks. For deaeration, the water is heated and disinfected at the same time.

Description

For treatment in the column deaeration system, the water is first heated to 72 °C or more in an integrated, regenerative heat exchanger. Heating reduces the oxygen solubility and simultaneously disinfects the water. The hot water is then dispersed at the top of the column. The column contains densely packed, thin stainless steel sheets arranged in such way that the water takes multiple paths as it flows down through the column. This maximizes the transfer surface and the contact time between the water and the strip gas (CO2 or N2). The strip gas is fed into the bottom of the column and flows upwards inside it in counter current to the water. The large partial pressure difference of O2 forces the oxygen out of the water into the gas phase. This fundamental scientific principle is described by Henry’s Law. At the top of the column the removed oxygen leaves the system as a gas, together with the undissolved CO2 or N2. Hot column deaeration requires very little strip gas. The O2 content of the deaerated water is permanently monitored. Therefore, the system is equipped with a high precision optical OXYTRANS sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2control. The virtually oxygen free water is collected at the bottom of the column. For further processing, it can optionally be cooled or additionally carbonated.

- High precision OXYTRANS sensor for process control

- Not sensitive against particles in water and low strip gas consumption

- Simultaneous disinfection of the water during deaeration

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 - 2.000 hl/h |

| Residual Oxygen | 50 ppb - < 10 ppb (lower on request) |

| Heat Recovery Rate | 92 % (higher on request) |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Heating Medium | hot water, steam |

| Options | double column design for lower height; different automation levels; remote maintenance access; in-line O2/CO2 measurement; column insulation; carbonation; cooling |

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652