Progressive Cavity CSF

Hãng sản xuất: CSF Pumps Inox VietNam

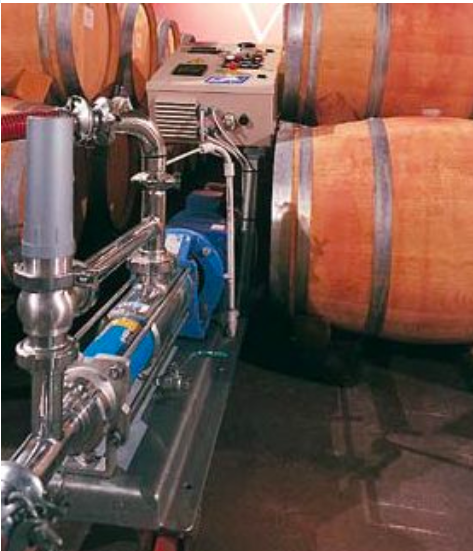

The progressive cavity pump is a positive displacement pump with one single rotating shaft. A stainless steel rotor and a rubber stator are the main pumping components. The rotor is a circular section single screw. The rubber stator is vulcanized inside a steel pipe.

Renowned for their versatility, different models are available in a choice of AISI 304, 316 stainless steel or in cast iron. Flow rates up to 130 m3/h, pressures up to 24 bar and temperatures up to 100 °C. Motorisation: direct motor, geared motor, variable speed motor, motor and pulley, gear motor with inverter.

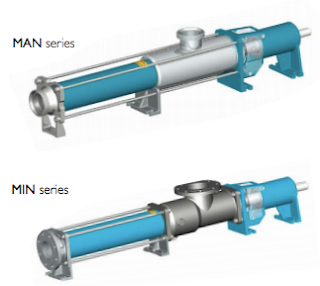

MA series

Foodstuffs execution Pumps for foodstuffs with a large suction chamber. Wetted parts are polished stainless steel with DIN threaded hygienic connections

MI series

Industrial execution Sturdy industrial pumps suitable for heavy duty requirements. Cast suction chamber and flanged connections.

The progressive cavity pumps can handle almost any kind of fluid up to 800.000 cps., including abrasive liquids and suspensions with

solids. The pumping action is delicate, without sudden pulsation and the flow rate is proportional to the rotational speed.

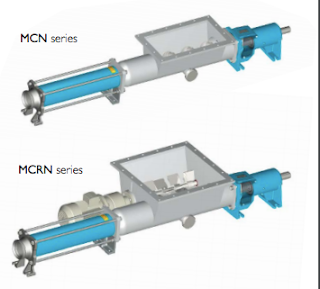

MC series

Features a hopper and a pre-feeding screw Version with a hopper equipped with pre-feeding auger screw suitable for viscous products that do not flow easily through pipes. The top part is equipped with a rectangular flange to which any type of conveyance system can be connected.

MCR series

Features a hopper, a pre-feeding screw and a vane crusher Version with hopper, pre-feeding screw and vane crusher, suitable for dense products in lumps, pieces or that tend to form a bridge around a normal screw feeder. The vane crusher is driven by an independent geared motor, to crush the product to be pumped, breaking down any large lumps and pushing them into the prefeeding screw

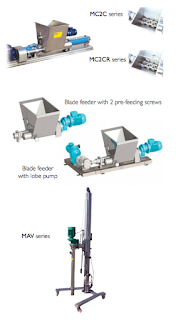

MC2C series

Features an hopper and 2 pre-feeding screws

MC2CR series

Features an hopper, 2 pre-feeding screws and 1 blade feeder Version with hopper and double synchronised pre-feeding screws, mounted below a vane crusher. The vane crusher blades chop the product and push it towards the bottom of the hopper. The two pre-feeding screws then push the product into to the pump stator.

Blade feeders with 2 pre-feeding screws

Version with hopper and double synchronised pre-feeding screw operated by a reduction unit. It can be manufactured as a simple feeder or in combination with a lobe pump.

MAV series - Vertical execution

MAV Series pumps are intended for product transfer and drum or container emptying applications, in which the suction port is plunged directly into the product. As standard, MAV pumps have a suction to discharge port dimension of 1100 - 1400 mm. It can be mounted on a drum-holding trolley, with a choice of either a manual sliding or an alternative pneumatic lift and lower system.

Ms. Trinh

Ms. Trinh trinh trinh

trinh trinh