Blender

Application

High Gravity Blending (HGB) is a process that allows producing different beers (brands) from one or few mother beers. Brewery productivity is thereby maximized for a comparatively small brew house capacity and a low number of fermentation tanks.

Description

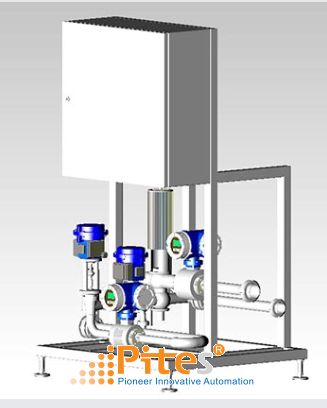

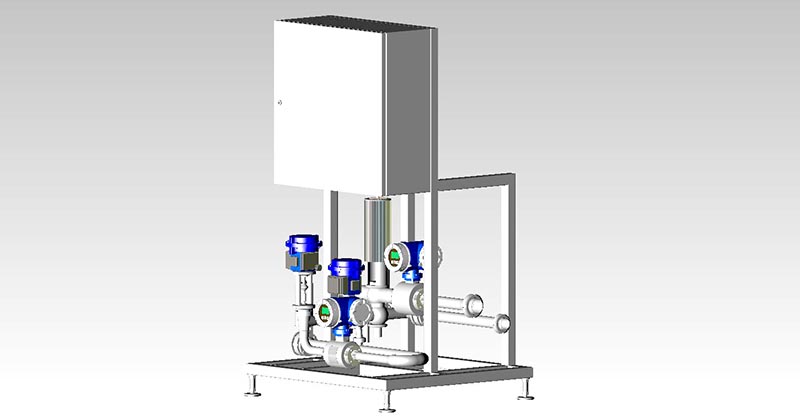

For High Gravity Blending wort with high extract content is produced. During fermentation this leads to a beer with higher original gravity and alcohol content. Later in the process the high gravity beer is blended with deaerated water to reach the desired final original gravity and/or alcohol content. If this is done directly in front of the BBTs or even directly in front of the filler, brewery flexibility is increased significantly. Different beers (brands) can be produced from the same mother beer. In that way, the brewery can quickly react to changing market demands. The flows and the content of original gravity and alcohol are permanently monitored and adjusted by ratio control. Therefore, the system is equipped with high precision flow meters and in-line sensors made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for alcohol control based on density and sound velocity measurement. Optionally, the Blender can be equipped with a Vortex-Venturi injector for combined supply of CO2 into the product. Systems combining High Gravity Blending and carbonation in one step are offered by Centec as compact CarboBlender skids.

- High precision in-line sensor technology for process control

- Integrated carbonation on demand (CarboBlender)

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 2 - 2.000 hl/h |

| Dosing Range Original Gravity | 7 - 20 °P |

| Dosing Accuracy Original Gravity | ± 0,05 °P |

| Dosing Range Alcohol | 0 - 10 Vol. % |

| Dosing Accuracy Alcohol | ± 0,03 Vol. % |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line O2/CO2/extract/alcohol measurement; carbonation/nitrogenation; pasteurization; buffer tank; cooling |

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652