WIEGAND SENSORS

Wiegand sensors are used as a pulse generator in multiple applications. The sensor needs no external power source and has no moving parts. Instead, it exploits the properties of a small diameter wire invented by John Wiegand.

When a magnetic field changes the magnetic state of the Wiegand wire within the sensor, a substantial output pulse is produced which can be used as a power source in an energy self-sufficient revolution counter.

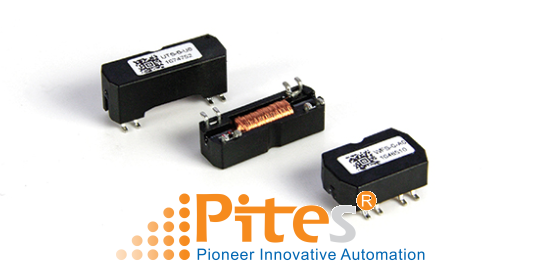

Wiegand sensor products from POSITAL reflect the knowledge from a full decade of experience using Wiegand-effect base revolution counters. The high performace sensors are assembled using SMD mounting technology and can be used for revolution counters in absolute rotary encoders as well as in other applications, e.g. gas or water meters.

Advantages

- No external power required – No batteries

- Longer lifespan

- Operates in harsh environments

- Non contact measurement – No mechanical wear

POSITAL’s Products

- Wiegand Wire Sensor for energy harvesting multiturn encoders using the Wiegand effect to generate energy from a rotating magnetic field

- Optimized for operation with the multiturn counter module iC-PMZ and iC-PMX from iC-Haus

- In surface mounted technology suitable for reflow process, RoHS 2 compatible

- Versions for 2,5 mm and 5 mm wire distances from top of seating plane

- High Pulse energy with typical 170 nJ average pulse energy

- Machine readable serial number provides perfect traceability

Important note: Energy Harvesting with Wiegand Wire Sensors within e.g. rotary encoders may be protected via worldwide patents and may require licensing

POSITAL’s History with Wiegand Technology

- 2004: First Wiegand Sensor design

- 2006: Series production of rotary encoders with Wiegand Technology. Partial assembly of Wiegand Sensors (part of production outsourced to subcontractor)

- 2012: Discontinuation of wire production at HID

- 2013: Acquisition of 2 Wiegand Wire production lines from HID incl. technical documentation. Consulting contracts with experts to ensure knowledge transfer

- 2014: Wiegand Technology Center opened in Aachen (Germany), Start of wire production in Aachen

- 2015: Assembly of Wiegand Sensors 100% insourced

- 2016: Production volume of 120,000 Wiegand Sensors.

Second production line for wire in US.

Second assembly line for Wiegand Sensors in Asia.

POSITAL multiturn encoders have been succesfully using Wiegand sensors since 2006. This energy harvesting system generates short, powerful voltage pulses sufficient to power the rotation-counting electronic circuit, even when the speed of rotation is very low. This solution enables the reliable measurement of multi-turn absolute positions without requiring access to an external power supply.

Wiegand Effect

The Wiegand effect technology employs the unique magnetic property of specially processed, small ferromagnetic wire. John Wiegand discovered a way to cause the magnetic field of this specially processed wire to suddenly reverse. When the magnetic field of this wire, called a Wiegand Wire, is reversed a sharp uniform voltage pulse can be generated. The pulse is referred to as a Wiegand Pulse.

![]() →

→ ![]() Applying a reverse field switches the core’s polarity, producing a large voltage spike.

Applying a reverse field switches the core’s polarity, producing a large voltage spike.

![]() →

→ ![]() As the reverse field continues to increase, the shell eventually switches polarity, giving rise to a smaller pulse in the same direction.

As the reverse field continues to increase, the shell eventually switches polarity, giving rise to a smaller pulse in the same direction.

![]() →

→ ![]() After saturating the Wiegand wire the reverse field is withdrawn.

After saturating the Wiegand wire the reverse field is withdrawn.

![]() →

→ ![]() Applying a magnetic field with the original polarity of the wire switches the core once again generating a large pulse in the opposite direction.

Applying a magnetic field with the original polarity of the wire switches the core once again generating a large pulse in the opposite direction.

![]() →

→ ![]() Increase of the eternal field will also switch shell polarity. The wire is back in the original state

Increase of the eternal field will also switch shell polarity. The wire is back in the original state ![]() and a full cycle completed.

and a full cycle completed.

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652