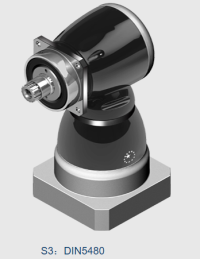

SC SERIES 3 AXES SERVO DRIVEN CNC ROBOT WITH TELESCOPIC ARM

Xuất sứ: USA

Nhà cung cấp: Pites

Hãng sản xuất: Apex Dynamics

OVERVIEW

3 AXES SERVO DRIVEN CNC ROBOT WITH TELESCOPIC ARM

- 3 Axes synchronized movement CNC servo drive robot with telescopic vertical arm.

- Free tracking control programming with pulse generator.

- Rigid Structure built for steady movement and precise positioning with heavy payloads

STANDARD 14 SPARE INPUTS AND 12 SPARE OUTPUTS FOR INTERFACING WITH OTHER ANCILLARY EQUIPMENT. EXTENSION UP TO 30 I/O ALSO AVAILABLE

1) Parts removal:

①.3 axes synchronized movements reduce complexity and cost to buildend-arm-tooling.

②.Able to reach parts with hooks and undercuts using unconventional paths such as curves, etc..

2) Stack and array:Each cycle can handle up to 9 stack areas with individual stack formats. Can also place parts onto 100 points on the same surface.

3) Insert and grid:Each cycle can place 9 different insertion materials into the mould, fed from a single point, grid pallet, or multi-station.

4) 3D path:The robot can follow teaching point-to-point path to move. It lets the track move smoothly and shorten the cycle time.

5) Inspection:Reject program: Detects signal from the moulding machine, set the reject partcount and places part in different area.

Inspection program: Places part in different area for QC inspection, for examplery 100 cycles.

Test-mould program: Allows checking of parts at the beginning of each automaticmoulding cycle before cycle counter starts. Weight program: Checks part quality from electronic weigh scale and separates defect parts.

Cycle counter: Counts the total number of moulding cycles. If counting good parts only, inspection cycle anddefect parts are not included in count total.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Support

Support