Position monitoring of the first billet in walking-beam reheating furnace- Giám sát vị trí của phôi thép đầu tiên trong lò hâm nóng chùm đi bộ

Xuất sứ: Germany

Nhà cung cấp: Pitesco Việt Nam

Hãng sản xuất: Proxitron

Position monitoring of the first billet in walking-beam reheating furnace

Type:

Article-No.:

Application:

LMB 100

52002

Non-contact distance measurement

Industry:

Steel industry – Hot Rolling

Customer / Field / Equipment manufacturer

Enduser BVS Srl. Italy, Rolling Mill for billets / Reheating Furnace from TS Italy.

Application description

The position of the front billet in the furnace must be checked before it is lifted and pushed outside the furnace. Customer wants to replace the present solution which enters the furnace and touches the billets.

Customer problem

Object temperature inside the furnace reaches 1250 °C. Customer does not want to have sensors mounted on the furnace wall: this implies complex works and is generally not feasible. He refused a light barrier made of transmitter and receiver and requested a single device which could look inside the furnace through the existing opening. A diffuse sensor would not work properly because of the presence of identical objects the background: a diffuse sensor could not discriminate between front and back billet.

Previous solution / Competitor product

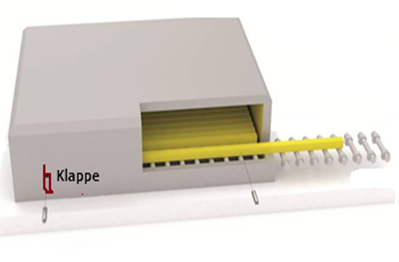

A complex mechanical system touching the billet, which is made of a chart travelling to the furnace opening and pushing a 1 m long rod inside, up to a defined distance (=billet position).

Proxitron solution

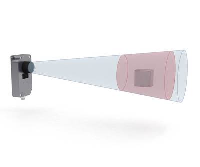

Customer will dismantle the chart and point Proxitron Laser distance measurement through the existing opening against the approaching billet. After reaching the expected distance, the billet can leave the furnace. Position need not be extremely precise, so an “active range” will be set. When billet lies in this range, switching output has a changed condition and the controller can activate the ejection device. In the following picture the red dot marked green shows where the laser light pointed during tests: this secondary window was opened for measurements to be taken and compared with the chart feedback. In the final installation the LMB will look through the opening now used by the mechanical chart.

Mr. Trí

Mr. Trí