ELAND CABLES, ARMOURED CABLE - SWA & AWA, BS 5467 SWA PVC BASEC Multi Core 0.6/1kV Cable, BS 6724 SWA LSZH BASEC Multi Core 0.6/1kV Cable, BS 5467 AWA PVC BASEC Single Core 0.6/1kV Cable

Nhà cung cấp: Pitesco Việt Nam

Hãng sản xuất: ELAND CABLES

ARMOURED CABLE - SWA & AWA

Eland Cables is a leading aluminium wire and steel wire armoured cable supplier offering a comprehensive range of robust and hard-wearing Low Voltage armoured and Medium Voltage armoured cables manufactured in accordance with British, European and International standards and specifications. These include SWA steel wire armour 3 core cable, and all sizes of these widely used armoured power cables with current ratings up to 33kV. For single core cables, aluminium wire armour - AWA - is used to prevent induced current in the armour. Armoured power cables are available with both copper and aluminium conductors as required.

Armoured cables are often referred to as steel wire armoured cables, SWA cable, mains power cable, single core power cable, and multi-core booklet armoured cable.

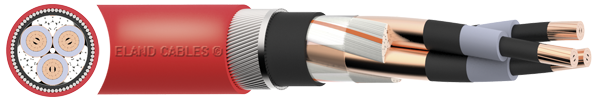

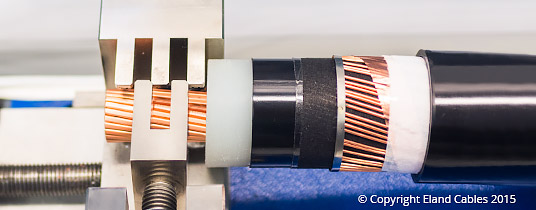

AWA & SWA ARMOURED CABLE CONSTRUCTION

Typically, the construction of an aluminium or steel wire armored cable comprises six components:

Conductor: plain stranded copper or aluminium

Insulation: materials such as cross-linked polyethylene (XLPE) provide high temperature resistance and excellent dielectric strength-providing enhanced electrical properties.

Bedding: a layer to create a protective barrier between the insulation and the armour.

Armour: a steel or aluminium armour provides mechanical protection to allow the cable to withstand the mechanical stresses to which it is exposed.

Sheath: the constituent parts of the cable are held together by a sheath offering a further level of protection. Black sheaths can be carbon-loaded for UV stability.

Voltage: voltage ratings of 600/1000V, 6.35/11kV and 19/33kV.

The armour provides additional protection where mechanical stress has the potential to cause damage to the cable, such as direct burial, outdoors or underground. The armour also enables the cable to withstand higher pulling loads. It should be noted, however, that the armour provides no protection for climatic conditions.

The construction of our various types of armoured cable (US spelling armored cable) differs according to their intended application and may also include protective screens and materials suited specifically to the installation conditions. We offer a comprehensive range of BASEC-approved armoured cables, manufactured in accordance with a number of British, European and International standards including BS5467, BS6622, BS6724, BS7835, BS EN 50267, IEC 60502 and BS EN 60332-1-2 (for single core cables).

Eland Cables' range of armoured cable is available with a Copper (Cu) or Aluminium (Al) conductor and with a Polyvinyl Chloride (PVC) or Low Smoke Zero Halogen (LSZH) sheathing, LSZH sheathings are recommended for use in high density enclosed areas, and are mandatory in some public places.

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652