3-Way Mixing Valve and Evaporator

Xuất sứ: Holland

Nhà cung cấp: PITESCO VIET NAM

Hãng sản xuất: Bronkhorst

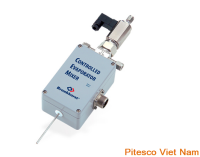

CEM EVAPORATOR W-303B

3-Way Mixing Valve and Evaporator

- Accurately controlled gas/liquid mixture

- Fast response

- High reproducibility

- Very stable vapour flow

3-way Mixing Valve and Evaporator

Bronkhorst® model W-303B CEM 3-way Mixing Valve and Evaporator is suited for precise vapour flow delivery, composed by mixing up to 1200 g/h H2O (3200 g/h IPA) with max. 100 ln/min of carrier gas at operating pressures between vacuum and 100 bar. The temperature controlled mixing device is used in combination with a (thermal or Coriolis) liquid flow meter and an MFC for carrier gas, together forming a Controlled Evaporation and Mixing (CEM) System.

Technical specifications

|

Performance |

|

|---|---|

|

Max. Kv-value |

6,6 x 10-2 |

|

Max. heating temperature |

200°C |

|

Mechanical /Electrical specifications |

|

|---|---|

|

Material (wetted parts) |

Stainless steel 316L or comparable |

|

Pressure rating |

100 bar(a) |

|

Max. ΔP |

5...40 bar (depends on Kv-value; contact your distributor for details) |

|

Process connections |

Gas and liquid inlet: compression type or face seal couplings; |

|

Seals |

Metal-to-metal |

|

Plunger |

Kalrez®; other on request |

|

Protection class |

IP40 |

|

Power supply |

Mixing valve: +/-15...24 Vdc; |

|

Power consumption |

Mixing valve: 4 W (max.); |

|

Heater capacity |

1000 W |

|

Connector 1 (temperature & safety) |

Amphenol 6-pin male |

|

Connector 2 (heater) |

Amphenol 5-pin male |

Mr. Trí

Mr. Trí