FLOW SWITCH FS05 BASED ON THE CALORIMETRIC PRINCIPLE

It is designed for flow rate monitoring of thermally conductive liquids. It is a simple flow velocity sensor with one or two switching contacts whereas each of them may have different flow velocity making/breaking points. Due to its construction, it is designed primarily as an OEM device used for substitution of mechanical flow switches in industrial processes.

Flow Switch FS05 key technical properties

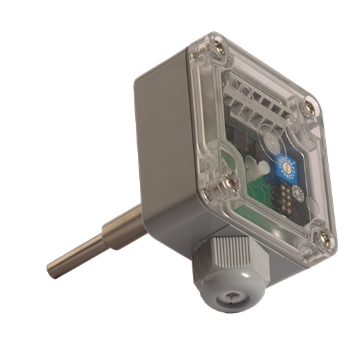

The operational status is displayed using 6 LEDs. Identification of contact making is displayed by two LEDs. The making contact/contacts are set using a 16-position micro switch. Electrical connection is provided with WAGO cage clamps on the printed circuit board of the evaluation unit, namely by guiding through the cable gland with a very simple installation.

We offer two standard lengths of the bar type sensor according to piping ID at the installation site. The customer may select a bar type sensor 65 mm or 125 mm in length as needed.

Using the 16-state switch, the user sets the flow rate limit (or limits). As soon as the flow drops below the user-defined limit, the status output is changed as well. The measurement cycle time ranges from 4 to 8 sec. Flow velocity sensor measurement range is 4÷200 cm/sec. If the piping is empty, the sensor behaves identically as in the case of zero flow rate.

Application of the flow switch in industry

Thanks to absence of moving parts, it is an ideal substitution for mechanical flow switches with short service life. Conversely, flow velocity electrical evaluation is a guaranty of long time stability of all parameters. It is used with advantage, e.g. in cooling systems or building applications. Another possible employment is, e.g. in the technology complex where it provides information on operation of the entire technology, or conversely, as a safety element protecting against empty piping, low flow quantity, etc.

Flow Switch FS05 and its main advantages

- Quick and easy installation

- High reliability

- Long service life

- Indication of contact making using LEDs

- Possibility of two switching positions

- Continuous control of the sensor for correct operation

- Sensor with a high IP rating

- Utilization in various ID piping

- Electrical connection using cable gland and WAGO clamp connectors

- Low purchase costs thanks to simple construction (OEM product)

Mr. Trí

Mr. Trí