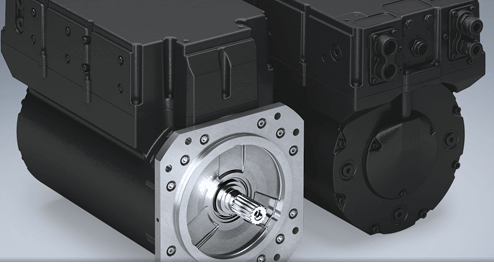

powerMELA®

Powerful permanent-field synchronous motors

Experience and spirit of innovation combined in the mobile drives concept powerMELA® - electric power and drive tech for mobile work machines, ships and commercial vehicle.

powerMELA® is a compact drive solution for hybrid and electric mobile machines and vehicles. The proven system is already being used in many different applications and was developed by Baumüller together with Sensor-Technik Wiedemann GmbH.

Functionality of the powerMELA® system

The powerMELA® drive concept consists of a permanently excited synchronous reluctance motor and an integrated four-quadrant frequency converter. In the hybrid concept with powerMELA®, a DC voltage is generated in the vehicle electrical system by a combustion engine using a combination of generator and frequency converter. With all-electric solutions, operation is exclusively by battery current. The electric motors are connected to the on-board power supply and drive the vehicle.

Advantages of the powerMELA® system

powerMELA®-Series

The powerMELA®-C series is a family of permanent magnet synchronous electric machines with integrated power inverters. They were developed specifically for mobile working machines, for use in both the main drive and auxiliary drives. The machines are liquid cooled and designed for 4 quadrant operation. The desired values for torque, voltage and speed control can be set over CAN bus.

eTruck - E-Mobility for functional vehicles & agricultural machines

Flexibility Through Decentralized Drive Concepts

Mr. Trí

Mr. Trí