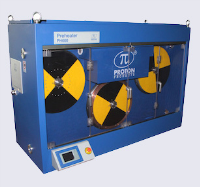

LN Series Lump & Neck Detector_Proton Vietnam, Thiết bị đo đường kính cáp, Proton PTC Vietnam

Xuất sứ: UK

Hãng sản xuất: Proton

- Accommodates object diameters from 0.4 to 25mm.

- Minimum flaw height of 40μm + 1% object diameter.

- Minimum flaw length of 0.5mm.

- Line speeds up to 2500m/min.

- Wire drawing lines.

- Wire and cable insulation extrusion and jacketing lines.

- Quality inspection during rewinding and coiling.

Ms. Trinh

Ms. Trinh trinh trinh

trinh trinh

Operating principle

Specifications